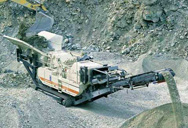

إعادة العمل دون الفجر، وتحطيم المعادن في الصين بعلامة تجارية عالية الجودة، ووحدة صياغة موحدة لصناعة المطاحن. وعلى مدى أكثر من 30 عاما، جرى التركيز على تصنيع معدات تفكيك المناجم، ومعدات تكسير المباني، ومعدات صنع المساحيق الصناعية، ومعدات البناء الخضراء، وتقديم حلول متخصصة ومنتجات مكتملة النمو، مما يعطي قيمة للزبائن.

لا تتردد في تقديم استفسارك في النموذج التالي. مدير المشروع سوف يساعد على فرز وتكاليف الإعداد

CPM 特色. 创新的工程学设计结合最新的制造技术,提供了最高品质的制粒机。 给客户带来最佳的生产能力和颗粒品质。 CPM能够提供高品质的设备、配件和服务,同时给客户提

More

您身边的制粒专家. CPM (California Pellet Mill) 是世界闻名的制粒机设计制造商,提供制粒线上的全套设备包括:粉碎机、制粒机、调质器、冷却器、膨化机、破碎机及相关配件。.

More

KAHL offers flat die pellet mills for various products, such as compound feed, biomass, straw and sewage sludge. The pellet mills have adjustable roller gap, lubricated bearings and

More

Bühler’s wide range of pellet mills and associated equipment covers everything needed for industrial pelleting. Solutions include feeders, conditioners, retentioners, dies and roller

More

Learn how to make biomass pellets from various materials with different pellet mills and production lines. Find the best pellet machine for your needs and get a quote online.

More

Feed Biofuel. Pellet mills, biomass. Pellet mills for biomass production. The ANDRITZ range of pellet mills offers reliability and high output for conversion of biomass into

More

2018.3.23 Our Mission. to be the leader in biomass pellet machinery. Make pellets. We have shared our experience and knowledgewith these ... Supports. From design, to production, packing, delivery and after... Our

More

Vertical Ring Die Wood Pellet Machine. Electric Flat Die Wood Pellet Mill. Wood Crusher Machine / Sawdust Making Machine. Carbon ball press machine. Briquette charcoal extruder. honeycomb coal briquette

More

That’s because our pellet mills are built to the highest possible standards in the world today. For more than 80 years, CPM has been leading the way in the design and manufacture of world-class pellet mills with the lowest operating costs and the highest long-term value imaginable. With every piece of pelleting equipment we sell, we take the ...

More

at a slightly lower production rate than a pellet mill designed for feed and fertilizer. Pellet Mill Working Principles: Raw material is placed into the feeding hopper, which leads to the pellet mill head, where the rollers and

More

with over 300 machines ready to ship from our warehouse in Chippewa Falls, Wisconsin. 1406 Lowater Road • Chippewa Falls, WI 54729 •. Pellet Masters offers the largest selection of in stock Grinders, Hammer Mills, and flat die Pellet Mills for production of feed and wood pellets in North America. We support our machines and our customers.

More

BioMax Pellet mill. The unique design of the BioMax makes it a robust, easy to maintain mill with high output and low operating costs. Made specifically for the very demanding task of producing biomass, the BioMax is designed for pelleting materials that require very high force while also taking on a high-volume of materials that traditional pellet mills cannot

More

XGJ series efficient wood pellet mill is our initiative patented products in China through meticulous research and development. This pellet mill Mahchine absorbs the quintessence at home and abroad, the heart part adopts"double-layerdie" as the unique structure;The rllers are made of abrasion-proof lloy sel, improving the using lifetime of spare parts

More

The pellet mill RWPR is capable of processing finely ground wood, straw, and other biomass particles, as well as sunflower hulls for industrial or household pellets. Operator-friendly The pellet mill is distinguished by its easy user guidance and its

More

Hennan Richi Machinery Co,Ltd has been designing, manufacturing and installing the most reliable and efficient feed pellet machine and wood pellet machine. After comparing some pellet mill companies, we decide to purchase RICHI products. Delivery, installation, operation and so on every detail, RICHI is doing very well.

More

Pellet press, pellet mill PM-200. ... PP200-PM pellet press 7.5 Kw Ø 200 mm die PM200M6-G hole Ø 6 mm and PM200K-G roller for wood. 3,990.00 € ...

More

Your partner for compacting your creation. As a global technology leader, we know how to pellet a wide range of materials. Supplying the full scope from continuously feeding the proper amount, conditioning it homogeneously to just the right condition before pressing to finishing with post pelleting applications like coating or cooling.

More

In the field of wood pelleting, we can look back on 25 years of experience in various industries: From the design of the pellet mill, logistics and production to the delivery and installation of the wood pelleting plant, AMANDUS KAHL takes over the complete process flow. AMANDUS KAHL builds pellet mills in 16 different sizes with a drive power ...

More

These substances and materials are pelleted using pellet mills. AMANDUS KAHL designs and manufactures pellet mills in different sizes and for different throughput capacities. Get informed here or contact us directly - together we will find the right solution for your project. Manufacturer of pelleting machines for wood, feedstuff and biomass in ...

More

2023.5.31 Section 1: Introduction Chapter 3: Pellet Mill Design. fluctuate due to the variation in feed ingredients and formulations, as well as to the pellet quality desired. The pellet mill manufacturer should be consulted as necessary for the ideal set-up regarding other applications or applications with non-typical ingredients.

More

2022.10.5 Biomass pellet applications: Wood that is unsuitable for other purposes is brought together, converted into a fine powder and then pressed through stainless steel grates at high pressure to form the short, solid, dense biomass pellet quickly and efficiently. Our flexible line of biomass pellet mill machines allow us to make pellets from ...

More

创新的工程学设计结合最新的制造技术,提供了最高品质的制粒机。. 给客户带来最佳的生产能力和颗粒品质。. CPM能够提供高品质的设备、配件和服务,同时给客户提供最低成本的运营方案。. 简而言之,CPM提供给您最有价值的整体方案。. CPM的各地代表都是制 ...

More

主要优点. 适用于各种配方. Kubex T 甚至可以加工难度非常大的高脂肪或高纤维含量饲料配方。. 生产效率高. Kubex T 是一款有效的制粒机,每小时能够生产高达 80 吨的 4 mm 粒状家禽饲料。. 能耗低. Kubex T 采用直接驱动,电机直接连接到主轴而无需传动系统。. 这 ...

More

2015.7.22 Working Principles of pellet mill. Material input into the pelleting chamber. Regulated material input into the pellet mill is important for maintaining consistent pellet quality. During the pellet production process moisture is released as steam. If the rate of material feed is greater than the productivity rate of the pellet mill, problems ...

More

2 天之前 Algeria’s annual production of 100,000 tons of poultry feed mill project is about to be put into operation. 10 tons per hour wood pellet production line in the United States put into operation. Russia’s 5-6t/h extruded aquatic

More

2023.6.28 Flat die pellet mills are commonly used for small to medium-scale wood pellet production. These machines consist of a stationary flat die and a rotating roller. The dried wood materials are fed into the pellet mill, and as the roller rotates, the material is pressed through the die holes, forming cylindrical pellets[4].

More

At the heart of SERVODAY's Pellet Mill Machine lies the precision-engineered Ring Die, a critical component that ensures the quality and consistency of pellet production. Crafted with meticulous attention to

More

2015.10.1 Each design has its own advantages and disadvantages. The two main types of pellet mill are the flat die pellet mill and the ring die pellet mill. The flat die pellet mill was designed around the turn of the

More

2014.5.23 A pellet mill (also called pellet machine, pellet press) is a type of mill or machine which is used to make pellets from powdered materials. A pellet mill is usually consisted of pellet die and rollers. The

More

7900 Series. The 7900 Pellet Mill is the workhorse and go-to pellet mill for many applications. Whether it is hard-running biomass, high-capacity animal feeds or anything in between, the 7900 is known for its dependability and versatility. Download Brochure >>.

More

2023.4.20 A wood pellet mill, sometimes referred to as a pellet press, is a type of mill that turns wood chips, sawdust, and other powdered raw materials (biomass) into pellets. The way pellet mills work is the complete opposite of how grinding mills do. Wood pellet machines work by fusing smaller materials to form a single large mass, which is then cut ...

More

2024.5.9 WOOD PELLET MILL. We provide you with industry-leading wood pellet mill machine products and 0.3-90t/h complete wood pellet production line solutions. Wood pellet mill is special pelletizer system for wood pellets production, which is built to the highest possible standards and designed to make your job easier, safer, and more efficient—and ...

More

2024.4.29 We are more than a pellet mill machine manufacturer, we are high and new technology RD in the field of pellet mill and briquetting machine. For small and large oil mill plant and flour mill plant, after years of development, our company has formed a modern industrial service model which integrates R D, production, sales, installation

More

The pellet mills are built to operate. 24 hours a day under tough running conditions to match the output requirements. 30 years of experience and more than 600 biomass pellet mills in operation around the globe. have proved the one piece gearbox to be the most robust, reliable and compact transmission principle. With the lowest operating costs.

More

TCPEL Pellet Machine has advantages of both horizontal ring die mill and flat die pellet mill. Furthermore, the machine features a built-in lubricating system to ensure a friction-free process. Step 7: Cooling of Pellets. As pellets come out of the pellet mill, they are hot. You might notice that they are discharging some moisture.

More

PelletIndia Counter current Pellet Cooler available up to 20 TPH Capacity. The hot pellets from the pellet mill enter the pellet cooler bin through the inlet rotary valve. The pellets are being cooled in the bin by air flow, which enters the bin through the discharge gate and leaves the bin through the air outlet. Pellet Cooler 5 Ton Per Hour.

More